NISSAHUB is new type of agile technology organizations offering services for the development and management of industry projects based on AI technologies, covering sustainable manufacturing domain

Main technology partner: Nissatech

Main product: Data-driven eco-quality management (d2port.rs)

Main Technologies

Selection of industry use cases:

Energy domain

Predictive maintenance for MV/LV transformers (Spain)

To detect transformer failures, patterns and correlations between parameters are identified from historical data (oil temperature, load, power…), defining the normal values (normal behavior) and triggering alarms when they deviate from the ordinary values.

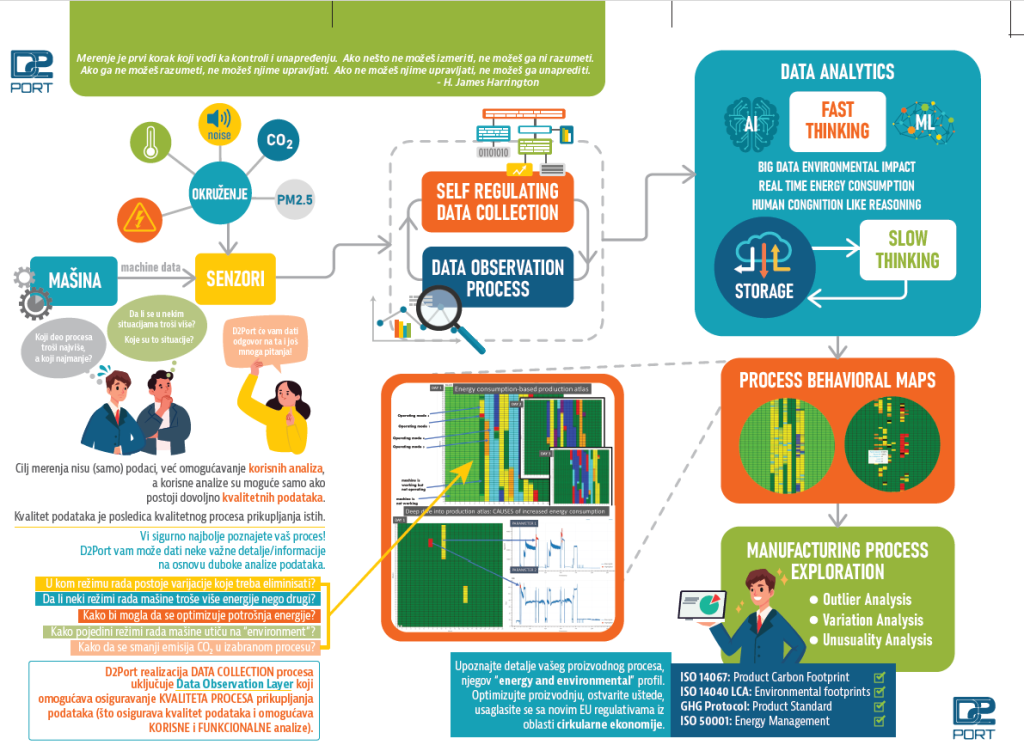

General approach: Digital twin from energy consumption data. Creation of machine behavior models by analyzing data from power sensors. The aim is to automatically derive machine working modes and analyze their energy characteristics. An efficient hardware infrastructure for sensing and transmitting data is being developed. It can be applied to any type of machine.

Oil&Gas domain

Automatically analysis and reporting on key processes in a drilling rig operation scenario (Netherlands)

The service uses the rig’s sensor data to automatically generate an objective description of the performance (KPIs) of the drilling process using an advanced hybrid analytics approach. The focus is on understanding the behavior of the drilling process in order to identify situations (and their causes) in which the process behaves sub-optimally.

Precise machinery

New approach to in-process quality control (Italy)

Highly dimensional and multivariable process monitoring and control. Such monitoring supports root cause analysis of scrap (as in the traditional approach) and enables real-time monitoring and analysis of variations in the production process to detect anomalies and deviations in the production process itself, thus reducing the scrap rate and increasing process capability.

Metal cutting (laser, plasma)

Predictive maintenance in metal cutting with Digital Twins (Serbia)

The main result is a predictive maintenance system that is able to detect anomalies in operation as soon as they occur or even before, but without any prior knowledge of the complex operation. Digital twin created from historical data.

Furniture industry

Eco-friendly production using the Green Digital Twin approach (Serbia)

GreenTwin models the behavior of the CNC woodworking machine in the context of energy consumption and environmental aspects to minimize the carbon footprint and improve health and safety in the workplace

Textile industry

Eco-friendly Quality Monitoring and Control (Serbia)

PET (Polyethylene terephthalate) production

GreenTwin approach for sustainable PET production (Serbia)

General approach: Green Digital Twin from energy consumption and air quality data (environment). Correlating energy consumption and air quality data to develop eco-friendliness models of machines. An efficient hardware infrastructure for data collection and transfer is built. It can be applied to any type of machinery.

Promoted systems:

Cog4Sol Cognition-driven predictive maintenance of Solar power plants

The vision is to create a new generation of the predictive maintenance solutions for middle-sized solar power plants which use the advanced AI and data analytics methods for predicting/analysing not only the trends in generated solar energy, but also the status of the entire solar and manufacturing infrastructure enabling a holistic predictive maintenance.

Main tangible outcomes are the system (SaaS) for holistic predictive maintenance for solar power systems and Cyber Physical Systems (CPS)-based infrastructure for easy deployable sensing for sustainable manufacturing.

The basis for the development of the proposed approach is the data which is collected from the solar power system (as energy production system) and the manufacturing process. The focus of the data processing approach is on acquisition, processing, and analysis of historical field data as well as the generation of respective data-driven models. In the nutshell, this leads to a digital replica of the assets, aka Digital Twin, whereas the intention to develop powerful operational models of the asset behaviour to be used in the maintenance analysis, incl. the possibility to react proactively on the so called early indicators of unusual behaviour.

Partially supported by

H2020 Innovation Action – This project has received funding from the European Union’s Horizon 2020 research and innovation programme under grant agreement N. 101017057

CognEcoQuality Cognition-driven eco-aware process quality

The vision is to enable SME-affordable (inexpensive, less interaction with domain experts and easy to deploy) process quality monitoring services, which consider product quality in the context of environmental friendliness and energy consumption, assuring so called eco-aware process quality, one of the key concept for realizing sustainable manufacturing.

Main goal is to develop (based on KITT4SME support and reusing existing assets of the solution provider SME), deploy and validate an AI-based software-hardware system for enabling a comprehensive monitoring, analysis and improvement of the eco-aware process quality in the manufacturing end user SME, with a very clear exploitation intension to offer that kind of the products/services for Europa-wide manufacturing SMEs

The basis for the development of the proposed approach is the data which is collected from manufacturing process related to the three main factors/waste of environmental footprint: Energy, Emission and Anomalies (material waste),measured in a non-intrusive way (without a direct intervention with machines), using external sensors (energy, air quality) and cameras. This heterogenous data will be processed using advanced AI methods to develop comprehensive models of the process behaviour regarding eco-aware process quality. Main challenge is to develop models for an efficient detection of new situatons when some eco aspects will be challenged (anomalies) and to understand how to react, realizing eco-aware process quality assurance.

The solution uses KITT4SME AIQuS Component (AI for Quality Systems)

Supported by